Welcome to Transflow Industrial Services Limited, your trusted partner in maintaining quality and control in industrial settings. If you’re looking for Riboflavin testing, then you’ve found the solution. Get in touch with us for Riboflavin testing and much more.

Request A Free Quotation

Fill out this form to get your free quotation from our experts – enquire today to lock in your quote for our Transflow Industrial Cleaning Services

What is Riboflavin testing?

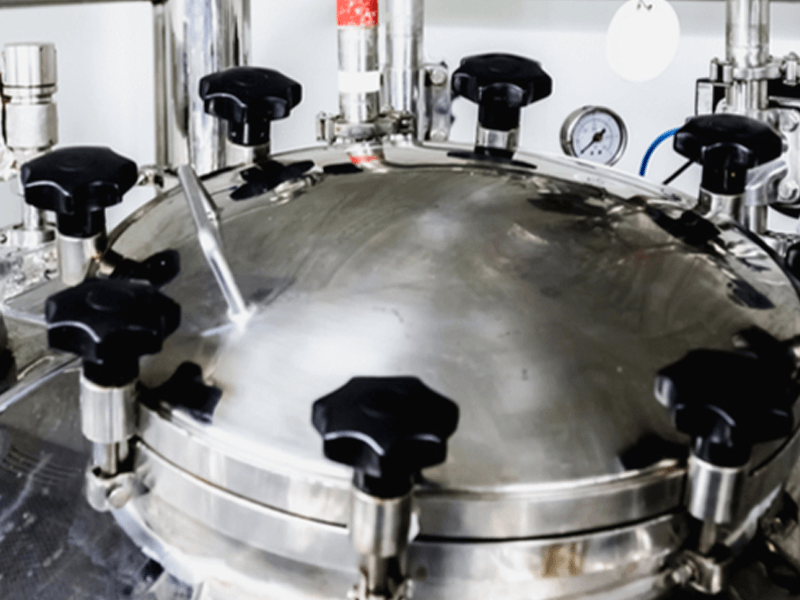

Riboflavin testing is a key factor in our quality assurance and control processes. Riboflavin testing detects leaks and damages in various systems, including pipelines, tanks, and vessels. Riboflavin or vitamin B2, is a water-soluble vitamin that can be used as a tracer dye in industrial testing. Riboflavin testing introduces the dye into a system to identify leaks and flaws. Riboflavin testing safeguards your equipment and allows for fast remedial action before issues evolve into major ones.

Industries That Benefit from Riboflavin Testing

We provide Riboflavin testing for many industries to ensure the integrity and safety of equipment and infrastructure. Riboflavin testing is suitable for pharmaceutical, chemical, food and water treatment settings.

Call Us For A Free Quote 020 8591 3875

How is Riboflavin testing done?

We carry out on-site Riboflavin testing to ensure full coverage of all vessel internals. We provide trained personnel to carry out our Riboflavin testing with Ultraviolet (UV) Light inspection to quantify the effectiveness of your spray balls. The riboflavin testing process goes as follows:

- Using spray equipment, the internals of the vessel are coated with a Riboflavin solution and observed under UV light. This provides a baseline to work from.

- The system CIP pumps are then used to spray, via the system spray balls, for a set amount of time and flow rate/ pressure.

- The results are then observed under UV light with photographs taken for reporting. This process can be repeated at different flow rates, and temperatures and for varied times to mimic the CIP process and ascertain optimal cleaning.

- The final report will include observed removal of Riboflavin, any areas of the vessel not contacted/ wetted during the process and the impact time and flow rate/ pressure on cleanliness. All of this process is achieved without vessel entry by personnel trained in working in GMP buildings.

For more information about how Riboflavin testing is done, please don’t hesitate to get in touch with our experts today. We can provide trusted advice and recommendations for Riboflavin testing.

The Importance of Riboflavin Testing

Riboflavin testing is essential in ensuring the safety and integrity of industrial equipment. Riboflavin testing can identify leaks and weaknesses early on. Therefore, Riboflavin testing prevents costly downtime, environmental contamination, and potential hazards to personnel.

FAQs About Riboflavin Testing

Is Riboflavin testing safe for my equipment?

Yes, riboflavin testing is non-destructive and safe for most industrial equipment when performed by trained professionals.

How often should Riboflavin testing be conducted?

The frequency of Riboflavin testing depends on various factors such as the type of system, its age, and regulatory requirements. We can provide tailored recommendations based on your specific needs.

Can Riboflavin testing detect small leaks?

Yes, Riboflavin testing is highly sensitive and can detect leaks as small as a pinhole.

Is Riboflavin testing environmentally friendly?

Yes, Riboflavin testing is biodegradable and environmentally safe, making it an eco-friendly choice for leak detection.

How long does Riboflavin testing take?

The duration of Riboflavin testing will vary depending on the size and complexity of the system being tested. Our team works efficiently to minimise disruption to your operations.

Can Riboflavin testing be performed on all types of systems?

Riboflavin testing is suitable for a wide range of systems, including pipelines, tanks, and vessels made of various materials such as metal, plastic, and concrete.

Is Riboflavin testing regulated?

While Riboflavin testing may not be directly regulated, industries often have standards and guidelines for leak detection and prevention, which may include the use of tracer dyes like riboflavin.

Can Riboflavin testing be used for preventive maintenance?

Yes, Riboflavin testing can help identify potential issues before they escalate, allowing for proactive maintenance.

How can I request a quote for Riboflavin testing?

You can request a quote for Riboflavin testing by getting in touch with us today. We can discuss your needs and provide a customised solution that meets your needs and budget.

Call Us For A Free Quote 020 8591 3875

Why choose us for Riboflavin testing?

30 Years of Experience

We have 30 years of experience in Riboflavin testing as well as degreasing, passivation and sanitisation services on purified water, WFI, pure steam and product systems.

Fully-Trained & Certified

We are fully trained and certified in CCNSG Safety Passport, COSHH Training, ADR Chemical, Confined Space Access, Job Specific Chemicals Services Training, Ferroxyl Testing of Welds and more.

Huge Client Portfolio

We have provided our services to a huge range of reputable clients and our portfolio includes ThermoFisher Scientific, AstraZeneca, Porton Biopharma, Merck, 3M Healthcare and many more.

See how Riboflavin testing can enhance your industrial operations and contact Transflow Industrial Services Limited today to schedule a consultation with our expert team.