Welcome to Transflow Industrial Services Limited, your trusted partner in maintaining the integrity and efficiency of industrial systems. If you’re looking for stainless steel pickling, then you’ve found the solution. Get in touch with us for stainless steel pickling and much more.

Request A Free Quotation

Fill out this form to get your free quotation from our experts – enquire today to lock in your quote for our Transflow Industrial Cleaning Services

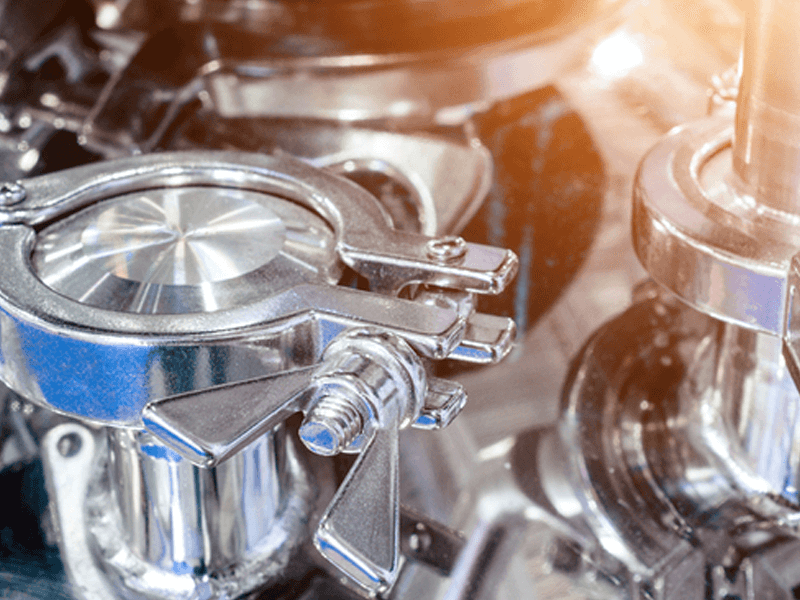

What is stainless steel pickling?

Stainless steel pickling is a crucial process in industrial maintenance aimed at removing impurities, contaminants, and scale from stainless steel surfaces. Stainless steel picklingnot only restores the pristine appearance of stainless steel but also enhances its corrosion resistance and longevity.

We employ advanced techniques and environmentally friendly solutions for stainless steel pickling. This ensures the optimal performance and durability of your stainless steel equipment and structures. Speak to us today for more information about stainless steel pickling for your industry.

Industries That Benefit from Stainless Steel Pickling

Numerous industries rely on stainless steel pickling to maintain their equipment and infrastructure. From pharmaceutical and chemical plants to food processing facilities and water treatment plants, any industry utilising stainless steel equipment can benefit from pickling services.

The Benefits of Stainless Steel Pickling

- Enhanced Corrosion Resistance

By eliminating surface impurities, stainless steel pickling fortifies stainless steel against corrosion. This ensures longevity and reliability and provides peace of mind against potential deterioration. - Improved Aesthetic Appeal

Stainless steel pickling restores the sleek, polished appearance of stainless steel. This enhances the overall aesthetics of industrial facilities and leaves a lasting impression on clients and visitors alike. - Optimised Performance

Clean, corrosion-resistant surfaces promote optimal performance of stainless steel equipment. Our stainless steel pickling minimises downtime and lowers maintenance costs, to boost productivity and profitability for businesses. - Compliance with Regulatory Standards

Stainless steel pickling helps industries comply with stringent regulatory standards by maintaining hygienic and corrosion-resistant surfaces. This is particularly relevant in the food and pharmaceutical sectors.

For more information about how Riboflavin testing is done, please don’t hesitate to get in touch with our experts today. We can provide trusted advice and recommendations for Riboflavin testing.

How is Stainless Steel Pickling Done?

- Surface Preparation

The stainless steel surface is thoroughly cleaned to remove any loose debris or contaminants. - Pickling Solution Application

A pickling solution, typically a blend of acids, is applied to the surface to dissolve scale, oxides, and other impurities. - Rinsing

After the pickling solution has done its job, the surface is rinsed with water to remove any remaining residue. - Passivation (Optional)

In some cases, passivation may follow stainless steel pickling to further enhance corrosion resistance by promoting the formation of a protective oxide layer.

Our expert technicians at Transflow Industrial Services Limited execute each step of stainless steel pickling with precision and care, ensuring optimal results and maximum satisfaction.

FAQs about Stainless Steel Pickling

What is the purpose of stainless steel pickling?

Stainless steel pickling removes impurities and contaminants from stainless steel surfaces to enhance corrosion resistance and prolong the lifespan of equipment.

Is stainless steel pickling safe for food-grade applications?

Yes, stainless steel pickling is safe for food-grade applications when performed by experienced professionals using appropriate techniques and materials.

How often should stainless steel equipment be pickled?

The frequency of pickling depends on factors such as usage, environmental conditions, and regulatory requirements. Our experts can assess your specific needs and recommend an appropriate maintenance schedule.

Can pickling damage stainless steel?

When performed correctly by trained professionals, stainless steel pickling does not damage stainless steel. In fact, it enhances its performance and longevity.

Is passivation necessary after pickling?

Passivation is not always necessary after stainless steel pickling, but it can further improve corrosion resistance in certain applications. Our technicians can advise on the suitability of passivation for your specific requirements.

How long does stainless steel pickling take?

The duration of stainless steel pickling varies depending on the size and condition of the stainless steel surfaces. Our team can provide a detailed timeline based on your project specifications.

Can stainless steel pickling be done on-site?

Yes, we offer on-site pickling services for your convenience, minimising downtime and disruption to your operations.

What types of contaminants does stainless steel pickling remove?

Stainless steel pickling effectively removes scale, oxides, rust, and other surface contaminants that compromise the performance and aesthetics of stainless steel.

How can I request a quote for stainless steel pickling?

You can request a quote for stainless steel pickling by getting in touch with us today. We’ll be happy to discuss your needs and provide a customised solution that meets your needs and budget.

Call Us For A Free Quote 020 8591 3875

Why choose us for stainless steel pickling?

30 Years of Experience

We have 30 years of experience in stainless steel pickling as well as passivation, biofilm removal and sanitisation services on purified water, WFI, pure steam and product systems.

Fully-Trained & Certified

We are fully trained and certified in CCNSG Safety Passport, COSHH Training, ADR Chemical, Confined Space Access, Job Specific Chemicals Services Training, Ferroxyl Testing of Welds and more.

Huge Client Portfolio

We have provided our services to a huge range of reputable clients and our portfolio includes ThermoFisher Scientific, AstraZeneca, Porton Biopharma, Merck, 3M Healthcare and many more.

Ready to experience the transformative benefits of stainless steel pickling for your industrial operations? Contact Transflow Industrial Services Limited today to schedule a consultation with our expert team.